Career To Chemicals

API(Active Pharmaceutical Ingredient)

API (Active Pharmaceutical Ingredient) means the active ingredient which is contained in medicine. For example, an active ingredient to relieve pain is included in a painkiller. This is called API. A small amount of the active ingredient has an effect, so only a tiny part of the active ingredient is contained in medicine. You will find the name and amount of the active ingredient contained in the medicine on the package of OTC (over-the-counter) drugs.

How APIs are made

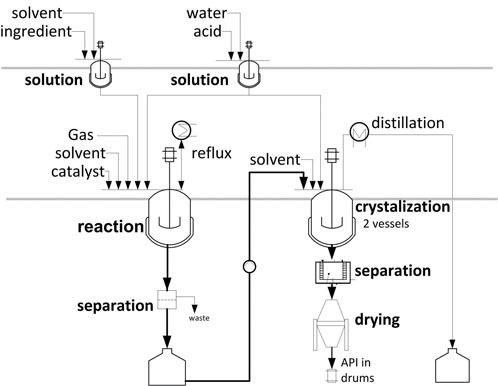

API and raw material are often confused due to the similar usage of the two terms. What is the difference? Raw material refers to chemical compounds that are used as a base to make an API. We purchase the raw materials from raw material or chemical product manufacturers both in Japan and internationally. When using the raw materials, as an API manufacturer we produce API in the large reactor in our plant. The API is not made by only one reaction from the raw materials but rather it becomes an API via several chemical compounds. The chemical compound which is in the process of becoming an API from a raw material is called an intermediate. Among the APIs we produce, there is an API which passes through over ten kinds of intermediates in a process when it changes from being a raw material into an API. After this long manufacturing process, it is purified until it reaches a very high degree of purity and finally becomes an API.

APIs

First of all, as an API manufacturer we think of how to make a chemical compound which becomes an API in the laboratory. We also have to consider the degree of concentration and which temperature allows a high quality of API to be manufactured efficiently. In order to find answers to these questions, our staff in the development department set about conducting a series of experiments. Once they have decided how to make the compound, our staff in the production department manufacture a high quantity of APIs using the large reactors in our plant. Our quality control staff then conducts analyses in the testing laboratory to examine whether the API manufactured is ultrapure. After testing, our quality assurance staff confirms that everything has been performed correctly in accordance with GMP from manufacturing of API to quality testing. As you can see, a considerable number of staff is involved in the production phase until an API is finally manufactured.

Career At Flavors & Fragrances

Aroma chemicals enhance the flavor or fragrance in a wide range of consumer products. Our certified food-grade, IFRA (International Fragrance Association), natural, kosher, and halal ingredients undergo scientific analysis and dedicated testing to provide safe and high-quality aroma chemicals for product formulation and development. A collaborative approach towards qualified vendors and compliance with internationally recognized regulatory requirements helps you meet the requirements of your customer

Natural Products

Support the natural designation of your formulation with our independently verified raw materials. Documentation supporting regulatory and quality compliance is available for all of our natural aroma chemicals. There are slight variations between US and European requirements for natural ingredients – all of our products meet EU Commission requirements, unless noted as US Natural.

Fragrance Product

Fragrance ingredients are abundantly used in cosmetics and household products both to impart perfume or mask odors. Consumers’ connection with fragrance through olfactory memory create greater demand in the market. We are dedicated to providing high-quality aroma chemicals for fragrance formulation that align with IFRA (International Fragrance Association) recommendations.

Custom synthesis

Custom synthesis means the exclusive synthesis of compounds on behalf of the customer, i.e., you can order a specific molecule that is only synthesized on your request on the scale, with the purity and with the specification or methods you require.

Custom Synthesis is optimal for synthesizing

- Chemical reagents

- Catalysts and ligands

- Building Blocks

- Materials for organic electronics

- Chemical standards/solutions

- Lead-like or drug-like compounds

- Chemical Service (Reaction screening, Special packaging, etc)

- Polymers

- And more…

- Save time and effort

- Ensure that your exact requirements are met: target structure, required amount and comprehensive analytics

- By using custom solution from Merck, your organization can access complex structures & air sensitive material with confidence.

- Our custom solution team has over 30 years of experience in handling pyrophoric materials

- Secure supply chain from lab scale to process/production.

- Nearby facilities allow for quick overnight delivery of products to US-based customers.

Capabilities & Made to order

- Gram to multi kg quantities

- Particular expertise in synthesis of homogenous catalysts, ligands, and reagents/building blocks as well as polymer chemistry and material science

- Customized packaging and customized specification.

- Custom products can be synthesized using methods designed by the custom synthesis team or methods designed by your chemists.

- Custom synthesis products are backed by analytical data to suit your needs.

- Products can be offered on an exclusive basis or stocked for quick reorder availability.

Our Expertise in

Active Pharmaceutical Ingredients

Driving Health and Wellness: Our legacy in API manufacturing spans over 50+ years, reflecting our deep commitment to improving global healthcare. We take pride in being at the forefront of pharmaceutical innovation, delivering high-quality, safe, and efficacious APIs.

Cutting-Edge Facilities: Our state-of-the-art manufacturing facilities are equipped with the latest technology and adhere to the most stringent quality standards and regulatory guidelines. We invest in innovation, efficiency, and sustainability to ensure that our APIs meet and exceed industry expectations.

Customized Solutions: We understand that each pharmaceutical project is unique. Our experienced team of chemists, researchers, and engineers collaborates closely with clients to develop tailored API solutions that meet specific project requirements, from initial research to large-scale production.